成都森格尔环保科技有限公司

Chengdu senge environmental protection technology co.LTD

Consultation Hotline:02865357899

Production, Sales and Development of Ion Exchange Resin

成都森格尔环保科技有限公司

Chengdu senge environmental protection technology co.LTD

Consultation Hotline:02865357899

Production, Sales and Development of Ion Exchange Resin

Contact person: Manager Liu

Location: 028-65357899

Mobile phone: 15680686111

Mailbox: chengdu@sgrhb.com

Fax: 028-65357899

Email: chinaresin@sgrhb.com

Website: www.sgrhb.com

Website : en.sgrhb.com

Address: 79 Jiujin Street, Wuhou District, Chengdu City, Sichuan Province

1. Types of ion exchange resins

The exchange capacity of different resins is different. Usually, the crosslinking degree of resin required by automatic sodium ion exchanger for boiler should not be less than 7. The crosslinking degree of resin should be 7, that is, 100 kg resin contains not less than 7 kg of crosslinking agent. The higher the crosslinking degree, the higher the strength of resin.

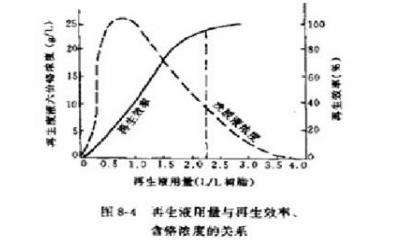

2. The dosage of regenerant

Theoretical analysis shows that the dosage of regenerant should be equal to the working exchange capacity of resin, but in fact, because the exchange reaction is reversible, the dosage of regenerant should exceed the theoretical dosage far enough to meet the requirement of sufficient regeneration strength. Increasing the specific consumption of regenerant can improve the regeneration degree of exchange resin, but when the specific consumption increases to a certain extent, it will continue to increase the proportion and increase the regeneration degree. It is not economical to use too high specific consumption because it is very little high. Therefore, the amount of regenerant is usually 3-4 times of the theoretical amount in the actual operation, and the working exchange capacity of the resin can be restored to 70-80% of the original.

Relation Diagram of Regeneration Liquid Consumption and Regeneration Efficiency

3. Flow rate of regenerant

The flow rate of regenerant should be controlled properly to ensure the full regeneration reaction. The flow rate of regeneration reaction mainly depends on the diffusion rate of ions, but at the same time it is related to the valence state of ions. The higher the valence state, the longer the reaction time is, the faster the flow rate of regenerant is, which is beneficial to the diffusion of ions, but reduces the contact time between regenerant and resin. However, the regeneration effect may be reduced, too small flow rate is not conducive to ion diffusion, and the regeneration effect will also be affected.

4. Concentration of regenerant

Generally speaking, the higher the concentration of regenerant, the higher the degree of regeneration. But when the dosage of regenerant is constant, the higher the concentration of regenerant, the lower the volume flow rate of regeneration solution, the shorter the contact time with resin and the uneven regeneration reaction may occur, the lower the regeneration effect, the shorter the water-making cycle and the number of regeneration times. With the increase of acid and alkali dosage, it is necessary to control the concentration of regenerant reasonably in production.

5. Temperature of regeneration solution

Increasing the temperature of regeneration solution can accelerate both internal and external diffusion. Although it is beneficial to improve the effect of resin regeneration, and high temperature can greatly improve the removal of iron, copper, oxide and silicon impurities in resin, the temperature of regeneration agent should not be too high due to the limitation of thermal stability of resin. 25-40 degrees is suitable.

6. Height of Resin Layer

When the height of resin layer reaches 30 feet (762 mm), the effect of flow rate on the exchange capacity of resin layer can be reduced to a relatively low level. Therefore, it is generally recommended that the height of resin layer be greater than 30 feet (762 mm).

7. Flow rate of regenerated liquid

Usually, the smaller the flow rate of regeneration liquid, the better the regeneration effect. However, too low flow rate of regeneration liquid will make the regeneration time too long and easily make the regenerant regenerate around the resin surface. Therefore, the flow rate of regeneration liquid is generally required to be 0.25-0.9 gpm/ft3 (or 4-6 m/h for downwash flow and 2-3 m/h for countercurrent regeneration).

8. Concentration of regeneration solution

According to the principle of ion balance, the exchange ability of resin can be improved by increasing the concentration of regeneration solution. However, if the concentration of regeneration agent is too high, the contact time between regeneration solution and resin will be shortened and the regeneration effect will be reduced. Generally, it is advisable to control the concentration of salt solution at about 10%.

9. Contact time between water and resin

The longer the contact time between water and SICHUAN ion exchange resin is, the more sufficient the exchange is. However, the water production capacity of the unit resin decreases, the shorter the contact time is, the more sufficient the exchange is, and the exchange capacity of the unit resin decreases, while the water production capacity of the unit resin increases. Therefore, reasonable contact time is very important for the economic operation of softener. Generally, 1.0-5.0 gpm/ft3 resin or 8-4 bv/h is recommended. The flow rate per hour is eight to forty times that of resin loading.

10. Quality of regenerant

The higher the purity of regenerant, the higher the regeneration degree of resin, and the less ion leakage of effluent. Therefore, improving the purity of regenerant and using softened water solution can improve the regeneration of resin.

Chengdu Senger Environmental Technology Co., Ltd.

Record No: 蜀ICP备19000327号

Powered by Xiangyun Platform

Contact person: Manager Liu

Location: 028-65357899

Mobile phone: 15680686111

Email: chinaresin@sgrhb.com